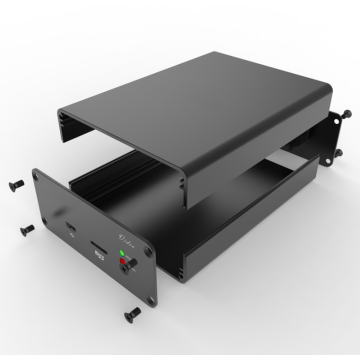

Dongji si concentra sulla fabbricazione di lamiere più di 10 anni e rende diversi tipi di parti di lamiera per attrezzature per l'energia solare in base ai disegni dei clienti . Tutti gli ordini OEM sono accolti, fornendo prodotti in acciaio inox, casse in alluminio, custodie in acciaio verniciato a polvere, armadietto metallico, scaffali metallici, scaffali metallici e così via. Forniamo servizi tra cui taglio laser CNC, Puncching CNC, stampaggio, piegatura CNC, saldatura TIG e rettifica, lucidatura, rivestimento a polvere, superficie spazzolata, montaggio in lamiera e assemblaggio cablaggio e cablaggio.

Servizio di lamiera OEM e prodotto in lamiera

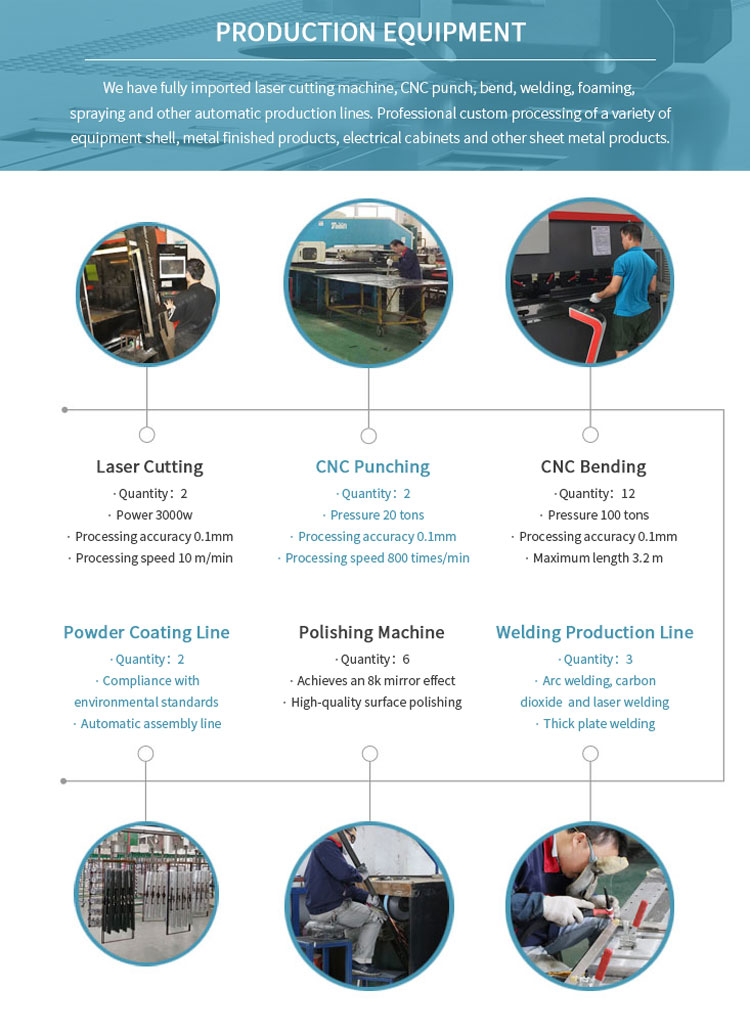

Il nostro servizio compreso il taglio laser, la pressione del punzone CNC, la piegatura del metallo, la saldatura in acciaio, la linea di saldatura automatica dell'acciaio inossidabile, la schiumatura della custodia, la spruzzatura del rivestimento della polvere di superficie, l'assemblaggio, il test e così via.

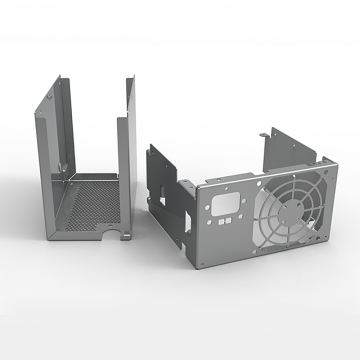

Il nostro prodotto principale è lamiera di lamiera, prodotti in acciaio inossidabile, elettrodomestici hardware, armadietto di controllo del robot, armadietto di controllo della rete e altri lavorazione della scatola della scatola, per fornire una soluzione generale per apparecchiature di auto-aiuto non standard.

Descrizione del prodotto

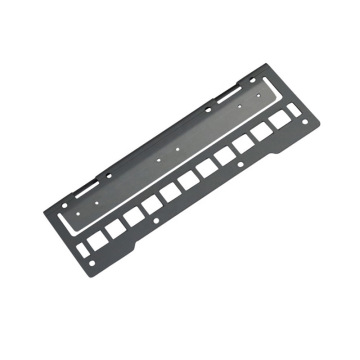

Product Name

|

Custom OEM Metal Parts Of Solar Energy Equipment

|

Materials

|

Stainless steel 201/304/316, sheet metal ( SPCC, SECC), aluminum alloy etc.

|

|

Processing

|

Laser Cutting ,Stamping, Punching , Bending, turning ,Welding, machining, surface treatment, and other General Fabrication Service

|

Sruface Treatment

|

Powder coating, Zinc plating, chrome plating, hot-dip, Silkscreen, polishing and so on.

|

Size

|

Customized

|

Industry Standards

|

ISO9001:2015; CE; TUV;SGS

|

Accuracy

|

+/-0.01 mm

|

Lead Time

|

15-35 days after receiving deposit

|

Drawing Format

|

3D/CAD: Dwg/IGS/STP/X_T

|

|

Usage

|

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications

|

Dettagli del prodotto

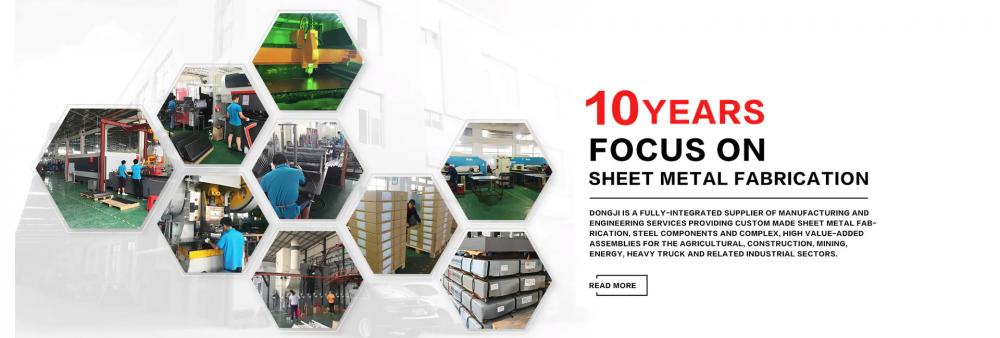

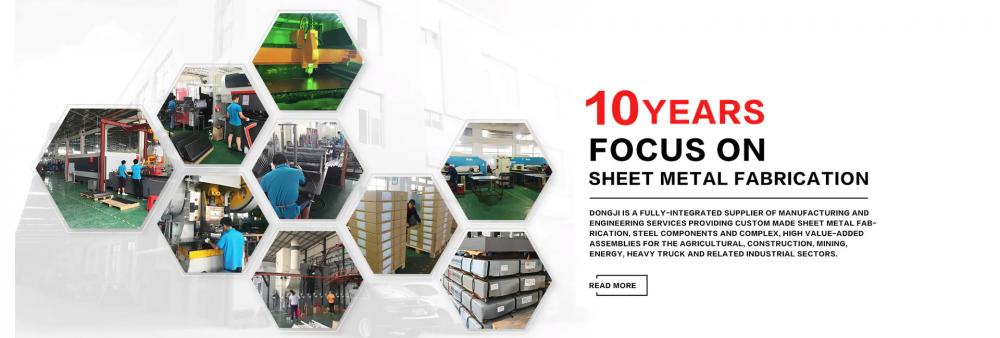

Profilo Aziendale

|

|

-

10 years experience in sheet metal fabrication

-

Dongji covers an area of over 38,000 square meters

-

Advanced manufacture equipments

-

Obtained ISO9001, CE, SGS,TUV, ETL,ROHS and other international certificates

-

Design, processing, assembly one-stop service

|

We have a technical team of more than

50 people and advanced manufacture equipments, and support full sheet metal fabrication solution for our customers.

It has obtained many international

ertifications such as ISO, CE ,SGS,TUV,ETL, ROHS and so on total more than 40 patents.

|

|

Servizio di fabbricazione

I nostri clienti

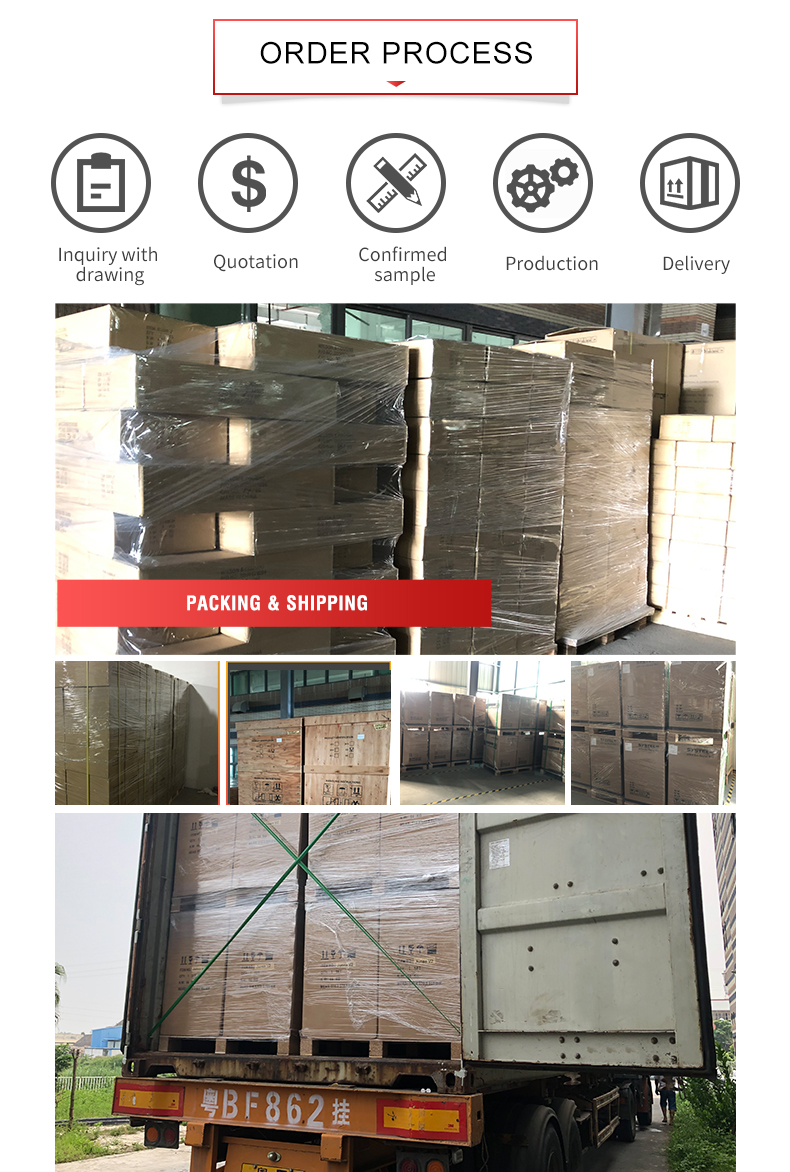

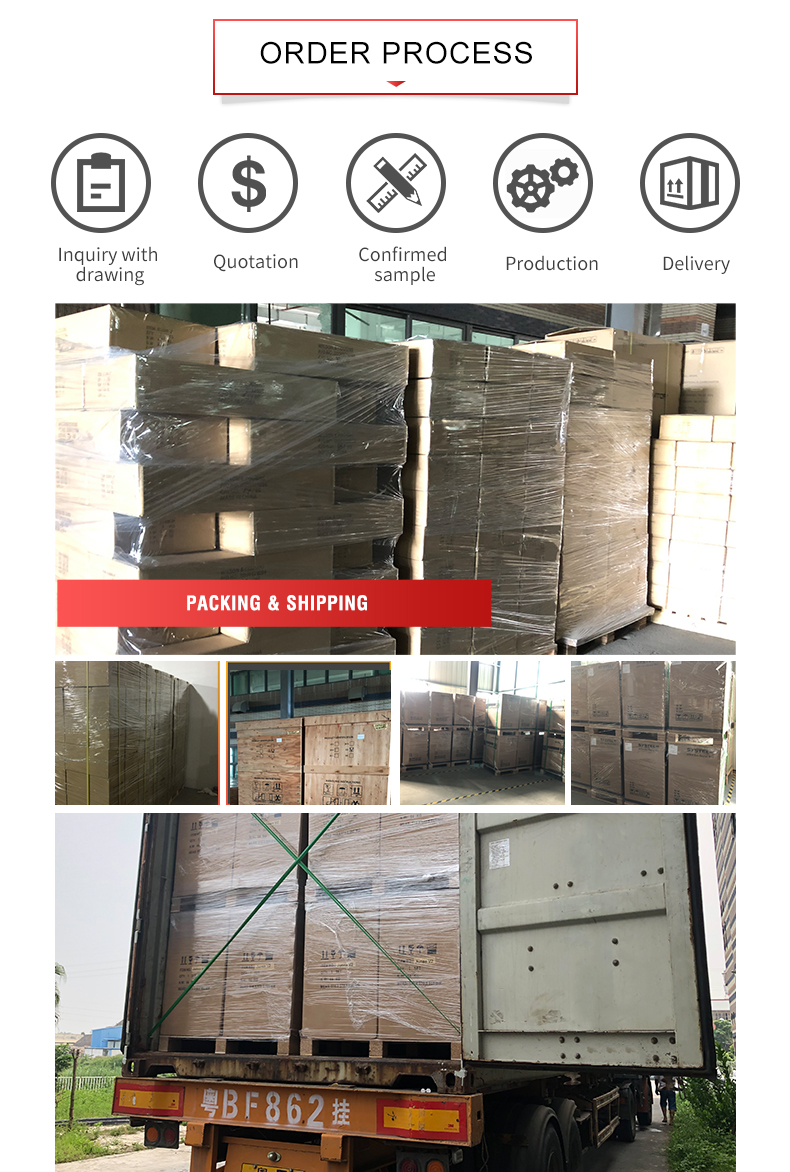

Imballaggio e spedizione

FAQ

Q1. Are you a manufacturer or trade company?

We are a factory covers an area of 30000 square meter, staff of nearly 200 people, including technical staff of more than 25%.Welcome to visit us.

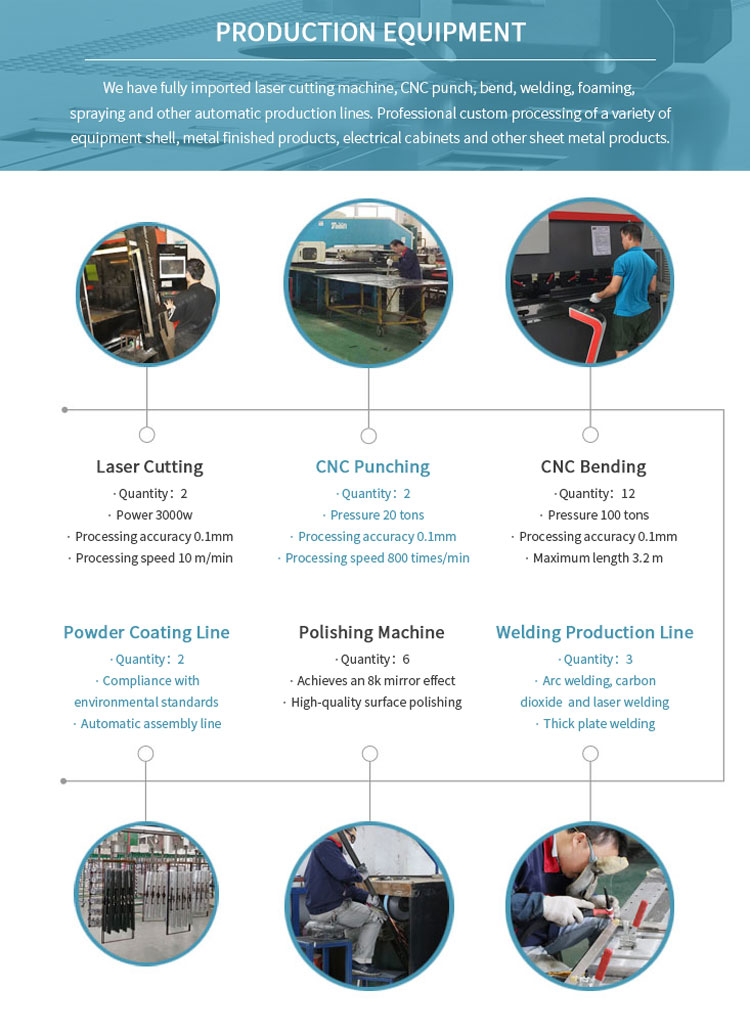

Q2. What kind of production service do you provide?

Laser cutting, CNC punching, CNC bending, Stamping, Welding,Polishing and so on. Welcome sent us drawing for quotation. All the projects will be confidential.We can also provide one-stop service, including mold and assembly.

Q3. How long should we take for a quotation?

After receiving detailed information (your 2D/3D drawings or samples), we will quote you within 3 days.

Q4. How about the lead time?

General speaking, 15 days for sample, 30 days for mass production. If you have any request, please contact with us.

WHY CHOOSE US?

1. We are sheet metal fabricator with ISO, CE, SGS and BV certificates for more than 9 years exporting experenice. We also

providing the assembing service.We have engineers for hardware, software and electronic.

2. We providing the complete service. Laser cutting, CNC punching, CNC bending, Stamping, Welding,Polishing, Power Coating,

Oxidization, Electrophoresis, Galvanization, Moulding and Assembling.

3. Most of our customers are from US, Euro, Australia.

4. Our products are with reliable quality and competitive price price.

|