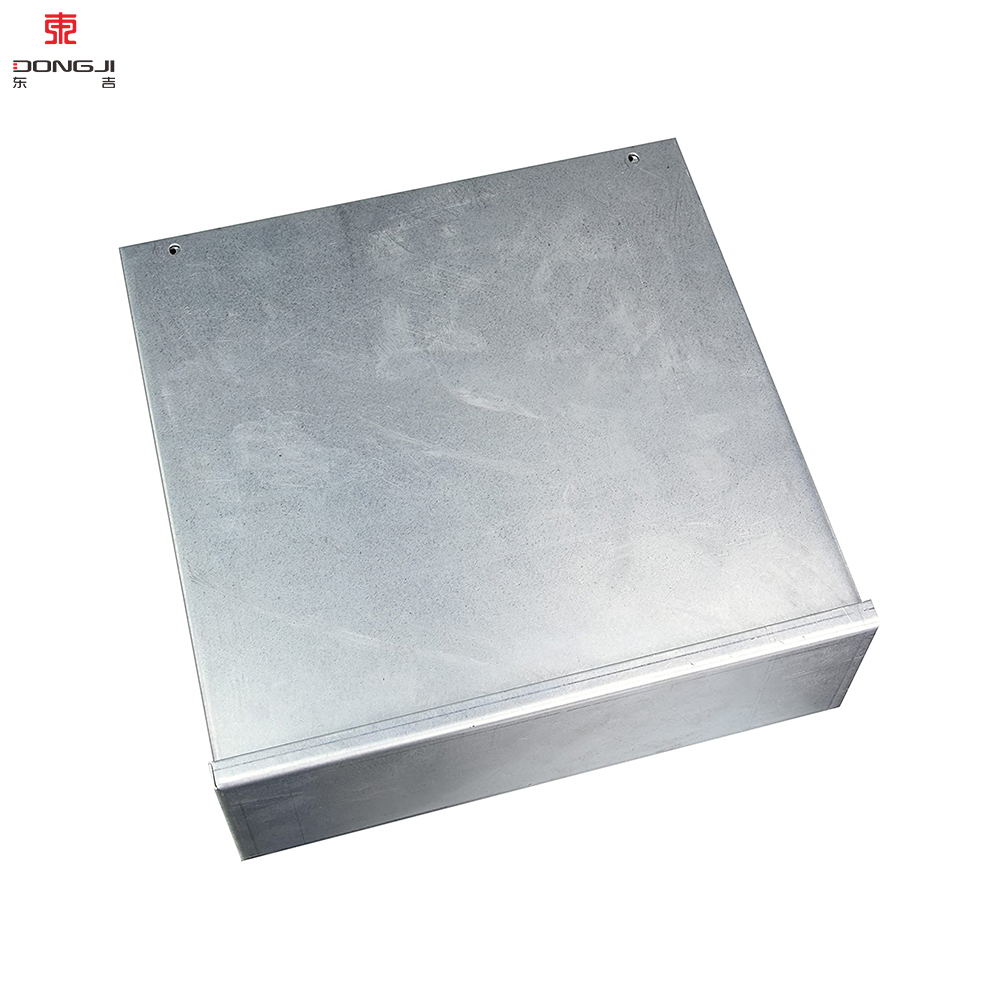

Scatola elettrica nichelata in lamiera OEM

Ottieni l'ultimo prezzo| Tipo di pagamento: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Quantità di ordine minimo: | 1000 Piece/Pieces |

| Trasporti: | Ocean |

| Porta: | Jiangmen,Shenzhen,Guangzhou |

| Tipo di pagamento: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Quantità di ordine minimo: | 1000 Piece/Pieces |

| Trasporti: | Ocean |

| Porta: | Jiangmen,Shenzhen,Guangzhou |

Modello: DJ-WIL-117

marchio: Dongji

Materiale: Acciaio a rotolo freddo

Dimensione: Costume

Applicazione: Scatola elettrica

Pacchetto Personalizzato: sì

Qualificazione: CE, UL, ISO, TUV

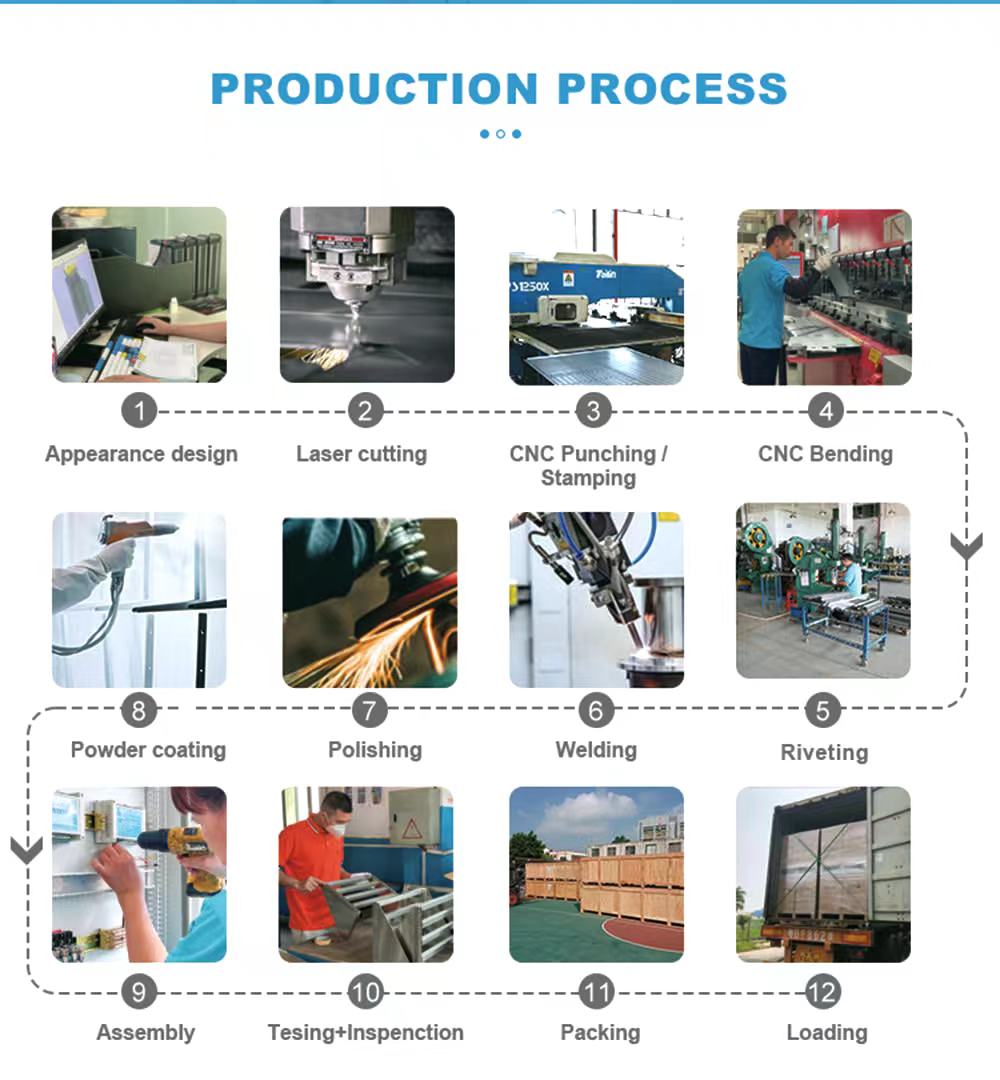

Artigianato: Taglio laser, punzonatura a CNC, flessione CNC, saldatura TIG, finitura superficiale,

Finitura Del Furface: Nickel in metallo placcato

| Unità vendibili | : | Piece/Pieces |

| Tipo pacchetto | : | Pacchetto di consegna internazionale personalizzato o regolare |

The file is encrypted. Please fill in the following information to continue accessing it

Dongji is located in Jiangmen, Guangdong, China, and has been focusing on the production of sheet metal casings. Our cold rolled steel produces durable electrical boxes through laser cutting, bending, welding and other processes. Through nickel plating, the product has a more metallic luster and is more durable.

|

|

Perché puoi fidarti di noi?

|

| ||||||||||||||||

Cosa possiamo fare?

|  | ||||||||||||||||

|  |

Q2. What should I do if the metal nickel surface can not meet my request?

Most of our sheet metal nickel coating items are customized. Including material, dimensions and other design. Of course we will give you some suggestions if you are not sure about the details.

Q3. How long should we take for a quotation?

We will quote you within 3 days after receiving detailed information (your 2D/3D drawings or samples.)

Q4. How about the lead time?

15 days for sample, 30 days for mass production.